Innovative Technologies for Energy Saving and Increase of Thermal Comfort

|

The first commercial application of the solar reflective technology was for leather especially black leather. these products are already in the market as leather for car seats and biker suits. The next diagrams show the totally different behaviour of standard black leather versus the new solar reflective leather. The total hemispherical reflection of two black leather samples has been measured over the wavelengths from 0.4 to 0.98 microns. Both black leather samples had the same visual appearance i.e. dark black. The Cool Black leather sample IFW TA 20767 showed a significant higher reflection at wavelengths in the near infrared. The solar reflection of the samples have been calculated according to ASTM E903-96 over the wavelength range 0.4 to 0.98 µm. The solar reflection of the standard black was at 5.83% and the Cool Black was at 24.39%.

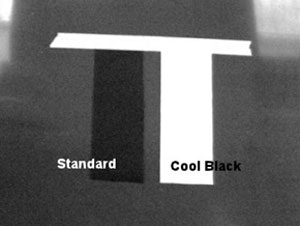

The following photograph has been taken with a special camera. It shows the image of the two black leather samples in the near infrared. The Cool Black appears white instead of black like the standard sample. This means for about 50% of the solar radiation this black leather appears white and so will not absorb as much heat from the sun like the standard black.

Both black leather samples have been exposed to artificial solar radiation at about 800 W/m² and the heat build up has been measured with a non contact infrared thermometer.

The standard black leather sample reached a surface temperature of 65°C and whereas the surface of the Cool Black leather sample reached only 36°C after the same time. This remarkable difference of 29°C in surface temperature will have a significant effect on the thermal comfort and will increase the life time of the leather itself. The photograph shows two black leather seats during a presentation. For one of the seats the leather has been has been prepared according to the solar reflective (SR) technology.

This picture shows a picture of the same seats taken with a special NIR camera. The right seat appears reflective white on this photo.

The next picture has been taken at the InterMot 2004 an exhibition for motor bikes and biker accessories. BMW has presented 4 different biker suits based on the Cool Technology,

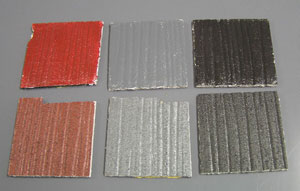

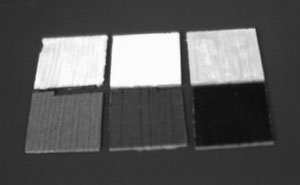

The next application was artificial leather based on PVC for automotive applications. The diagram shows the spectral performance of a standard black PVC sample versus a black PVC sample based on the new technology.

A picture of the samples has been taken with the special NIR camera.

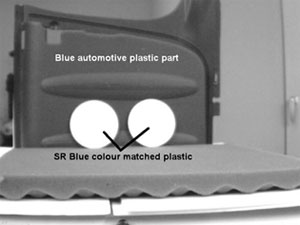

The following photograph shows an automotive plastic part out of Polypropylene with two colour matched samples based on the new SR technology.

The same picture has been taken with the NIR camera.

There are more applications for the SR technology like for buildings and construction coming soon. Samples for vinyl window frames based on the SR technology are in preparation.

The same articles as seen with the special NIR camera.

|